Developing the manufacturing process can be one of the most time- and resource-intensive aspects of pharmaceutical development. Staying competitive requires leveraging cutting-edge tools that enhance efficiency, reduce costs, and improve overall process performance. One such tool is Computational Fluid Dynamics (CFD), a branch of fluid modeling that simulates fluid systems, and has emerged as a transformative technology for optimizing manufacturing processes, from early design stages to full-scale production. By simulating complex fluid behaviors, heat transfer, and chemical reactions, CFD empowers engineers and scientists to design better systems, troubleshoot challenges, and make data-driven decisions. This blog explores the fundamentals of CFD, its applications in process development, equipment design, and regulatory support, as well as its role in driving innovation and streamlining operations in pharmaceutical manufacturing. Whether looking to enhance process understanding, optimize equipment design, or stay ahead in regulatory submissions, CFD is an invaluable tool for modern pharmaceutical development.

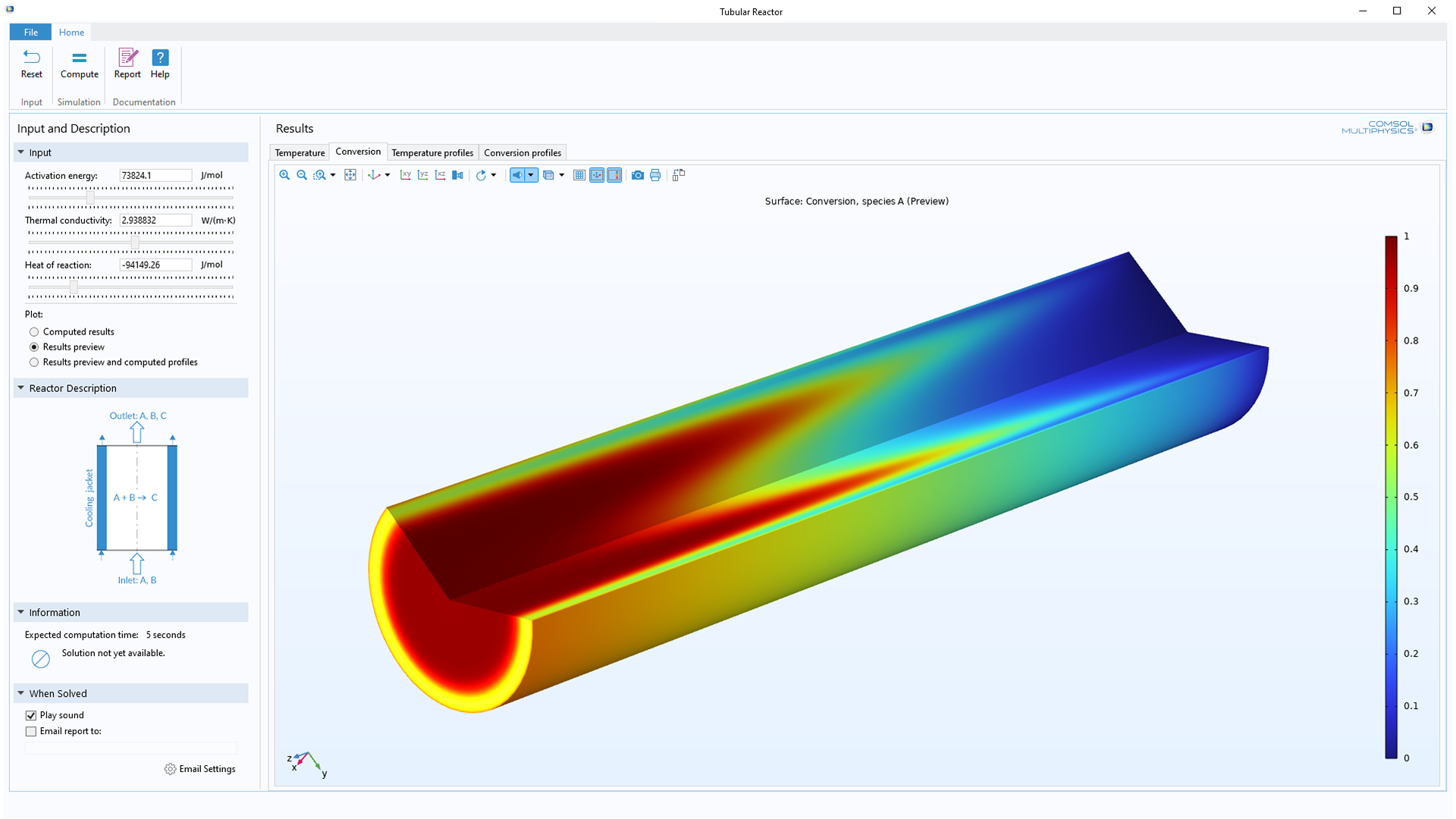

Simulation of a CFD propylene glycol reactor model application. Image made using COMSOL Multiphysics® software and provided courtesy of COMSOL

The Fundamentals of CFD

CFD is a mechanistic modeling approach that is primarily based on the principles of the Navier-Stokes equation, which describes fluid motion. CFD allows engineers and scientists to simulate fluid behavior under various conditions. The simulated results improve understanding of the system and decrease the need for costly and time-intensive experiments.

CFD models can incorporate heat and mass transfer, as well as chemical reactions, making them capable of simulating complex manufacturing processes. By leveraging these capabilities, it is possible to optimize both process conditions and reaction conditions in a single framework. Moreover, CFD can be used for both batch and continuous manufacturing processes, depending on the needs of the project to save significant time and resources. It can simulate equipment performance under different operating conditions to help select the best process parameters to limit the number of experiments during development and avoid costly changes down the line.

CFD Applications in Process Development

Optimization of Design and Operation

Whether designing a process on the bench scale or scaling it up for commercial production, numerous factors contribute to optimization, including equipment constraints, operational modes, and the balance between efficiency and robustness. These complexities can make process optimization difficult, particularly as changes may be required once the process development is already well underway. CFD provides a way to simulate these complexities early in development, offering insights into how adjustments to flow rates, temperatures, or other variables can improve efficiency or optimize process performance (Armstrong et al. 2019).

For example, in continuous manufacturing using plug flow reactors (PFRs), CFD can model the trade-off between conversion and throughput. This predictive modeling can serve as a supplement to the experimental data (and in some areas, replace it) needed to make data-driven decisions and reduce the likelihood of costly late-stage changes to the process. Such insights are invaluable in determining optimal operating conditions that maximize product output without impacting quality. In the biotech sphere, CFD has been used for mixing studies to determine mixing requirements for maintaining oxygen levels in fermentation bioreactors while minimizing shear that could potentially cause cell damage (Sharma et al. 2011).

Optimization of Facility and Equipment Design

In addition to process design, CFD can be employed during the equipment selection phase of facility design. Engineers can model custom geometries to simulate how different pieces of equipment—such as reactors, mixing tanks, or chromatography columns—will perform under various conditions. This allows for informed decision making, ensuring that investments in equipment are cost effective and aligned with the operational needs of the process. For example, a CFD model of a mixing bag for buffer preparation could be used to identify the ideal mixing time and speed at which homogeneity is achieved and reduce unnecessary time spent on mixing, thereby reducing process duration (Oshinowo et al. 1999). CFD can also be used to troubleshoot existing equipment and identify parameters that could potentially be impacting product quality (for example, mixing speed and corresponding shear experienced by the drug substance/product).

CFD and Critical Process Parameters

One of the key challenges in process development is identifying the parameters that have the greatest influence on critical quality attributes (CQAs). Critical process parameters (CPPs) of a manufacturing process are known to have a direct impact on the CQAs of a pharmaceutical product. While traditional methods like design of experiments (DoE) and one factor at a time (OFAT) experiments are commonly used to establish acceptable operating ranges for CPPs, they may not capture all the interactions between parameters. CFD, however, can simulate a wider range of conditions and provide a deeper understanding of these interactions, and can remove confounding factors such as operator-to-operator variability that may be present in experimental data. This information on parameter interaction can also be used to generate a complete DOE for reference when constructing an experimental DOE to avoid collecting data from regions of the design space that are not useful.

For instance, CFD can help pharmaceutical and biotechnology companies set more robust acceptable ranges for process variables by identifying unexpected interactions between parameters (Hörmann et al. 2012). This can help avoid nonconformance events that might otherwise disrupt manufacturing. Using CFD to model these scenarios can lead to a more robust process that is better equipped to handle variations in operating conditions. In addition, data that may be difficult or infeasible to collect experimentally (such as fluid streamlines, heat flux surfaces, reaction profiles, etc.) can be generated easily via CFD. These visuals can be quite useful when communicating complex topics to audiences who may not have extensive knowledge of the pharmaceutical industry.

CFD and Regulatory Applications

When preparing submissions to regulatory agencies like the FDA, process data collection becomes a major undertaking. The FDA has recognized the potential of in-silico methods like CFD to complement traditional data-gathering approaches (Morrison et al. 2018). These simulations offer an efficient means to evaluate processes, potentially reducing the need for at-scale studies.

While specific FDA guidelines for CFD use in pharmaceutical manufacturing are still limited, there is clear momentum behind the use of computational models (in fact, the FDA provides funding to academic research on this topic to be used in the assessment of market applications). One 2023 guidance on computational modeling in medical devices suggests that CFD could play a more prominent role in pharma in the near future, especially as companies seek to streamline development timelines. As regulations evolve, having well-validated CFD models could become essential in demonstrating process stability and control during regulatory submissions.

Challenges of CFD

While CFD provides numerous benefits, it does pose some challenges. The accuracy of a CFD model depends heavily on how well it represents the actual process. In some cases, such as when submitting data to a regulatory agency, the model must be extensively validated against experimental data to ensure its reliability. This validation process can be time consuming and resource intensive, particularly if the model is being used in a Good Manufacturing Practice (GMP) environment. In addition, there are a variety of CFD software available (COMSOL Multiphysics, Ansys, OpenFOAM, etc.), many of which are costly or proprietary, and can make implementation more difficult.

However, for early stages of development, internal optimization, increased process understanding, or reference for experimental design, CFD can be employed more flexibly. While it is important to ensure the model behaves as expected, the level of validation required can be tailored to the needs of the project. This flexibility makes CFD a powerful tool for both early-stage development and regulatory submissions when used appropriately.

Conclusion: CFD’s Role in Pharma Development

CFD offers tremendous potential for optimizing and troubleshooting pharmaceutical manufacturing processes. From early-stage process design through post-approval changes, CFD models provide valuable insights that can save time, reduce costs, and improve process performance. As the field of pharmaceutical manufacturing continues to evolve, the role of CFD is likely to expand, making it an increasingly valuable tool for companies looking to streamline development pipelines.

At Syner-G, we recognize the game-changing potential of Computational Fluid Dynamics in pharmaceutical manufacturing. From early-stage process optimization to ensuring compliance with evolving regulatory standards, our team of experts leverages advanced modeling techniques to deliver tailored solutions that improve efficiency and reduce costs. With a proven track record of helping companies navigate complex manufacturing challenges, Syner-G is uniquely positioned to provide the expertise you need to succeed.

Interested in learning more about how Syner-G can support your process development and optimization goals? Contact us today to explore how partnering with Syner-G can transform your operations and drive innovation in your manufacturing processes.